How does a bottom sealing machine seal the bottom of packages?

Leave a message

In the packaging industry, the bottom sealing machine plays a crucial role in ensuring the integrity and functionality of packages. As a dedicated bottom sealing machine supplier, I am excited to share with you the intricate process of how these machines seal the bottom of packages. This blog will delve into the science behind the sealing process, the different types of bottom sealing machines, and their applications.

The Science Behind Bottom Sealing

Bottom sealing is a process that involves joining the two sides of a package's bottom to create a secure closure. This is typically achieved through the application of heat, pressure, or a combination of both. The goal is to create a strong, airtight seal that prevents the contents of the package from leaking or spilling.

Heat Sealing

Heat sealing is one of the most common methods used in bottom sealing machines. It works by applying heat to the plastic film or material of the package, causing it to melt and fuse together. The heat is usually generated by a heating element, such as a hot bar or a heated roller. Once the material has melted, pressure is applied to ensure a proper bond.

The temperature and duration of the heat application are critical factors in heat sealing. If the temperature is too low, the material may not melt sufficiently, resulting in a weak seal. On the other hand, if the temperature is too high, the material may overheat and become damaged. Therefore, it is essential to carefully control these parameters to achieve the best results.

Pressure Sealing

Pressure sealing involves applying pressure to the two sides of the package's bottom to create a seal. This method is often used in conjunction with heat sealing to enhance the strength of the bond. Pressure can be applied using a variety of techniques, such as mechanical presses, pneumatic cylinders, or hydraulic systems.

The amount of pressure applied depends on the type of material being sealed and the desired strength of the seal. For example, thicker materials may require more pressure to create a strong seal, while thinner materials may require less pressure to avoid damage.

Adhesive Sealing

Adhesive sealing is another method used in bottom sealing machines. It involves applying an adhesive to the two sides of the package's bottom and then pressing them together to create a bond. Adhesive sealing is commonly used for packages made of paper, cardboard, or other non-plastic materials.

There are several types of adhesives available for sealing packages, including hot melt adhesives, solvent-based adhesives, and water-based adhesives. The choice of adhesive depends on the type of material being sealed, the application requirements, and the environmental conditions.

Types of Bottom Sealing Machines

There are several types of bottom sealing machines available on the market, each designed to meet specific packaging needs. Here are some of the most common types:

Vertical Form Fill Seal (VFFS) Machines

VFFS machines are widely used in the packaging industry for sealing the bottom of bags and pouches. These machines form the package from a roll of film, fill it with the product, and then seal the bottom and top. VFFS machines are highly versatile and can be used for a variety of products, including food, pharmaceuticals, and consumer goods.

One of the key advantages of VFFS machines is their high speed and efficiency. They can produce a large number of packages per minute, making them ideal for high-volume production. Additionally, VFFS machines can be easily integrated into existing packaging lines, allowing for seamless operation.

Horizontal Form Fill Seal (HFFS) Machines

HFFS machines are similar to VFFS machines, but they form the package horizontally instead of vertically. These machines are commonly used for packaging products such as cookies, crackers, and other dry goods. HFFS machines offer several advantages, including precise filling and sealing, as well as the ability to handle a wide range of package sizes and shapes.

Rotary Bottom Sealing Machines

Rotary bottom sealing machines are designed for high-speed production of packages with a round or oval shape. These machines use a rotary sealing mechanism to apply heat and pressure to the bottom of the package, creating a strong and consistent seal. Rotary bottom sealing machines are commonly used in the beverage and food industries for packaging products such as bottles, cans, and jars.

Inline Bottom Sealing Machines

Inline bottom sealing machines are used for sealing the bottom of packages that are already formed and filled. These machines are typically integrated into a packaging line and can be used for a variety of package types, including bags, pouches, and cartons. Inline bottom sealing machines offer several advantages, including high speed, precision, and flexibility.

Applications of Bottom Sealing Machines

Bottom sealing machines are used in a wide range of industries for packaging various products. Here are some of the most common applications:

Food Industry

In the food industry, bottom sealing machines are used for packaging products such as snacks, cereals, frozen foods, and beverages. These machines help to preserve the freshness and quality of the food by creating a tight seal that prevents air and moisture from entering the package.

Pharmaceutical Industry

In the pharmaceutical industry, bottom sealing machines are used for packaging drugs, tablets, capsules, and other medical products. These machines ensure the safety and integrity of the products by creating a sterile and airtight seal.

Consumer Goods Industry

In the consumer goods industry, bottom sealing machines are used for packaging products such as cosmetics, toiletries, and household items. These machines help to protect the products from damage and ensure their proper presentation.

Industrial Goods Industry

In the industrial goods industry, bottom sealing machines are used for packaging products such as hardware, electronics, and automotive parts. These machines help to protect the products from dust, moisture, and other environmental factors during storage and transportation.

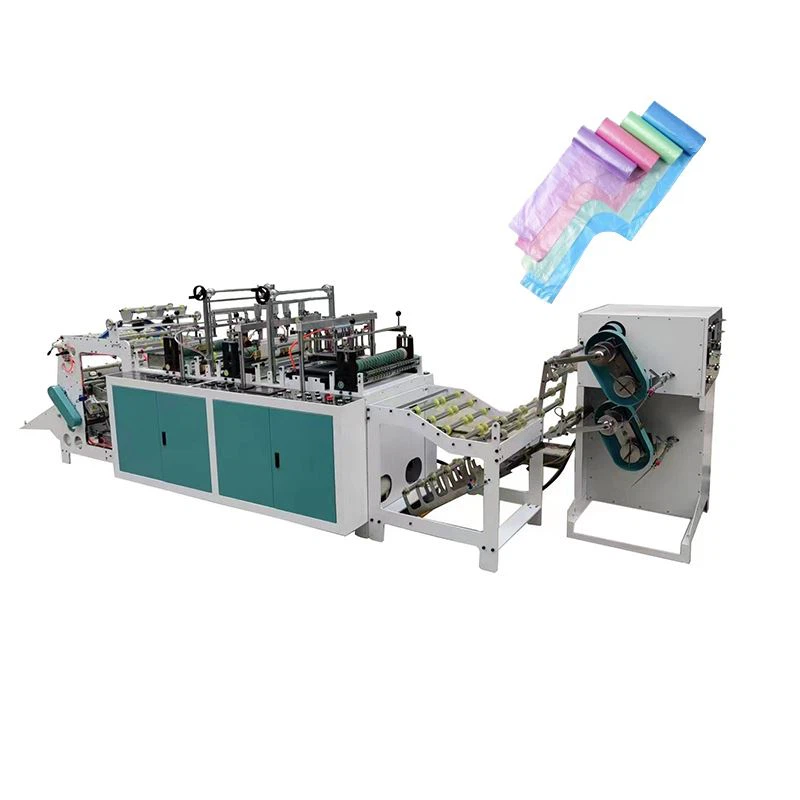

Our Bottom Sealing Machines

As a leading bottom sealing machine supplier, we offer a wide range of high-quality machines to meet the diverse needs of our customers. Our machines are designed with the latest technology and are built to last, ensuring reliable and efficient operation.

In addition to our bottom sealing machines, we also offer a variety of other packaging machines, such as the Double Line Bag On Roll Making Machine, the Sandwich Folding Machine, and the Impulse Seal Flying Knife Bag Making Machine. These machines are designed to work together seamlessly, providing a complete packaging solution for our customers.

Contact Us for Purchase and Negotiation

If you are interested in our bottom sealing machines or any of our other packaging machines, we encourage you to contact us for purchase and negotiation. Our team of experts is available to answer your questions, provide technical support, and help you find the right machine for your specific needs.

We understand that every customer has unique requirements, and we are committed to providing customized solutions that meet your exact specifications. Whether you are a small business or a large corporation, we have the expertise and resources to help you achieve your packaging goals.

References

- Packaging Machinery Manufacturers Institute (PMMI). (2023). Packaging Machinery Technology.

- Association for Packaging and Processing Technologies (PMMI). (2023). Trends in Packaging Machinery.

- Grocery Manufacturers Association (GMA). (2023). Packaging Guidelines for the Food Industry.